How many trees are your power supply choices saving?

We all hear the importance of CO2 emissions and their contribution to man-made climate change, but few understand how companies actually monitor and report on emissions to support sustainable development planning.

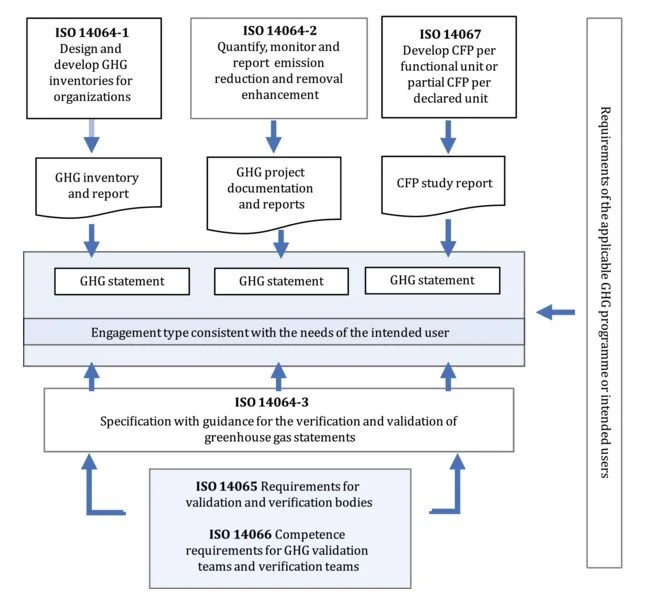

This process is fully covered by the GHG Protocol and the ISO14060 family of standards. The GHG Protocol is a guidance tool that offers detailed calculation methods to calculate and report emissions but does not offer formal certification. The ISO 14060 series of standards provides a structured framework for GHG accounting, including mechanisms for third-party verification which ensures the accuracy and consistency of the reported data alongside the ability to certify the data.

The GHG Protocol is most commonly used to split emissions into ‘Scopes’; These are Scope 1 (direct emissions ), Scope 2 (indirect emissions), and Scope 3 (supply chain emissions) which are then broken down further into various topics.

Whilst there are simplified guides for small businesses (pb13310-ghg-small-business-guide.pdf (publishing.service.gov.uk)), these are typically limited to Scope 1 (mostly addressed by changing vehicle fleets to EV) and Scope 2 (addressed by changing to green energy sources). However, Scope 3 becomes increasingly challenging with product level reporting, especially when sourcing from a third party where CFP certification is required. Consequently, many product suppliers are now implementing (or migrating to) the ISO14060 family of standards.

Figure 1 illustrates the relationship among the ISO 14060 family of GHG standards;

Fundamental to this is ISO 14064-1 which addresses the quantitative measurement, reporting, and verification of a company's GHG emissions (Corporate Carbon Footprint CCF). This is built on by ISO 14067 which specifies requirements and guidelines for quantifying emissions at the product level.

ISO14064-1 has 6 categories of emission reporting. Categories 1 and 2 map directly to GHG Scope 1 and 2 emissions. Categories 3-6 then map to Scope 3 supply chain emissions. This makes it easier to report Product level CFP certified via ISO14067 and reported against relevant ISO14064-1 Categories for the customer to map to their GHG Scope 3 reporting.

However, the challenge here is that the ISO14067 certification is limited by the boundary conditions used, namely the sourcing and manufacturing of the products and not the actual use of the product as those conditions are generally unknown to the product supplier.

The customer then must make a judgement on actual product use for inclusion in their Scope 3 reporting. As a worst-case scenario, where a product is developed for 24/7 operation, this is the limit of use and may incur considerable C02e over the installed base. In the past, mitigating actions were limited to;

a. Utilise a Carbon Offsetting scheme

This is increasingly unpopular following EU agreement to amend Directives 2005/29/EC and 2011/83/EU as regards to “empowering consumers for the green transition through better protection against unfair practices and better information” which then prohibits products and services to be promoted as 'climate neutral' when using carbon offsetting schemes: 1289669EN.pdf (europa.eu)

b. Develop higher efficiency products.

With psu products, this is covered by Eco-Design regulation which sets MINIMUM efficiency limits, although many companies are now realising the benefits of utilising a higher efficiency design vs minimum standards as the cost increases are far less than the Scope 3 emissions gains over the product lifecycle.

HOWEVER, there is also ANOTHER consideration that innovative companies are starting to realise. Actual product usage varies considerable over the installed base, so the CO2e is greatly reduced when reporting ACTUAL product usage rather than an assumed worst case. This was the basis for the psu demo that Salom has created using the Avnet IoT Connect service;

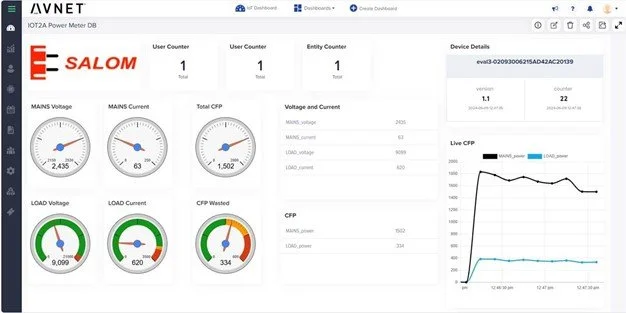

Salom IoT enabled psu with Avnet IoT Connect service for real time reporting

The mains input power and current were monitored alongside load voltage and current, then backhauled over an IoT connection to Avnet Silica’s ‘IoT Connect’ dashboard. The dashboard was then used to display the data alongside the Mains line CO2e and 'wasted' CO2e due to the inefficiency of the psu under test. The advantage of this is that multiple devices acting as a proxy for the installed based can then be used evidentially to support accurate GHG Scope 3 reporting and in doing so, reduce emissions over those assumed in a worst-case scenario.

This is discussed further in the Avnet Silica ‘We Talk IoT' podcast where the use of data can be used to support this new business model: https://my.avnet.com/silica/resources/podcast/ (Episode 57)

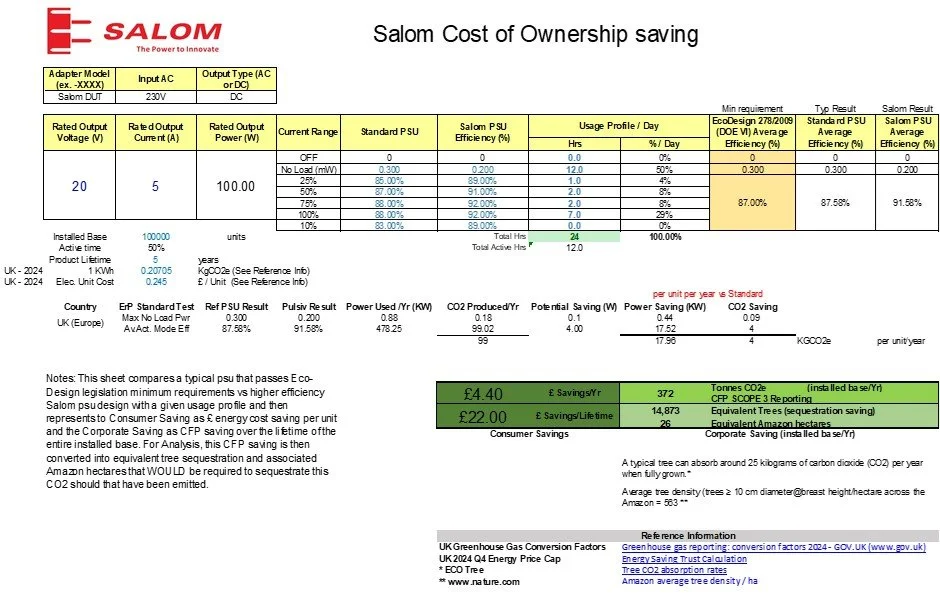

So how important is this really? The graphic below compares the gains of a more efficient psu with such accurate load profile usage vs a standard psu compliant to Ecodesign 2019/1782 regulation adopting DOE Level VI minimum limits, as reported in the podcast example;

Salom custom template for modelling enhanced psu value (Consumer and Corporate savings)

As can be seen, the consumer benefits from a reduced cost of energy to use the product which on its own may be considerably higher than the complete psu cost. However, the Corporate savings are even more substantial over the installed base representing a significant reduction in CO2e over the installed base which equates to an even more significant area of the Amazon as a representation of the amount of trees that would be required to sequestrate the CO2e difference had that been emitted!

In summary, actual power usage MAY be less than you thought if you can monitor this and a psu with efficiency levels exceeding the standard requirements is good for the consumer, the corporation and the planet …. so is this on your roadmap?

If you’re a leader in sustainable consumer electronics and are looking for a complementary sustainable power solution partner, come talk to us.

Andy Richardson – CEng MIET , info@salomeurope.com Vice President Business Development, Salom Europe Ltd

About Salom: Salom is a leading global volume manufacturer of high quality power solutions for a range of markets. As a manufacturing partner for global brands, Salom has produced in excess of 3Bn power suppliers since our formation. Salom products are trusted by some of the most successful electronics companies in the world, quietly and efficiently powering devices across the globe for more than 50 years.